Continuous Flight Auger piles

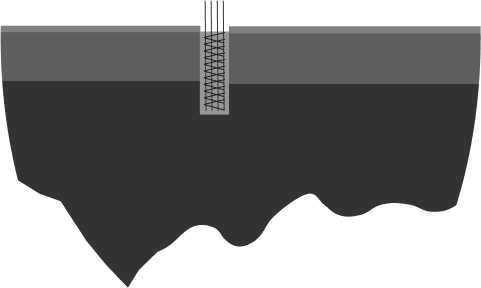

Continuous Flight Auger piles is the only such safe and reliable method of installing piles in sandy, peaty, and watery soil. CFA pile drilling technology is applied when it is not feasible to install piles in an ordinary manner that would safely reach the immovable sediment layer and retain the pile walls. Continuous Flight Auger technology ensures safe and proper displacement of soil to the surface from the place of a soon-to-be pile by drilling it with a hollow-stem auger. Then, the borehole is filled with a grout through the hollow stem, followed by insertion of a reinforcement cage, providing even better reinforcement. The result – safe and quality piles in a more expeditious manner.

No matter the function of the building, the safe and proper base is of the utmost importance. CFA drilling technology allows proper insertion of drilling piles, that provide firm support, into an immovable sediment layer for further placement of supports needed for the following construction.

We offer you the technology of continuous flight auger for drilling foundation piles up to the depth of 9 meters. A special auger is used for drilling. A borehole is filled with concrete through a hollow stem within the auger. The auger is slowly withdrawn from the borehole. Soil does not crumble into the borehole cavity, the entire borehole cavity is filled with concrete as the auger is slowly withdrawn. Finally, a reinforcement cage is inserted into such boreholes only after the concrete has been filled.

The method of CFA foundation drilling allows to install continuous piles in watery and shifting soil. When these piles are installed before the construction process, the piles are left protruding as per the requirements of the construction project for further laying of grillage foundation.

Continuous Flight Auger drilling is perfect for those who want to take care of withstanding soil shifting, especially within the boundaries of the land parcel or near adjacent buildings, prevent landslides or protect other buildings, protect against floods.

Continuous Flight Auger piles

Continuous Flight Auger piles is the only such safe and reliable method of installing piles in sandy, peaty, and watery soil. CFA pile drilling technology is applied when it is not feasible to install piles in an ordinary manner that would safely reach the immovable sediment layer and retain the pile walls. Continuous Flight Auger technology ensures safe and proper displacement of soil to the surface from the place of a soon-to-be pile by drilling it with a hollow-stem auger. Then, the borehole is filled with a grout through the hollow stem, followed by insertion of a reinforcement cage, providing even better reinforcement. The result – safe and quality piles in a more expeditious manner.

No matter the function of the building, the safe and proper base is of the utmost importance. CFA drilling technology allows proper insertion of drilling piles, that provide firm support, into an immovable sediment layer for further placement of supports needed for the following construction.

We offer you the technology of continuous flight auger for drilling foundation piles up to the depth of 9 meters. A special auger is used for drilling. A borehole is filled with concrete through a hollow stem within the auger. The auger is slowly withdrawn from the borehole. Soil does not crumble into the borehole cavity, the entire borehole cavity is filled with concrete as the auger is slowly withdrawn. Finally, a reinforcement cage is inserted into such boreholes only after the concrete has been filled.

The method of CFA foundation drilling allows to install continuous piles in watery and shifting soil. When these piles are installed before the construction process, the piles are left protruding as per the requirements of the construction project for further laying of grillage foundation.

Continuous Flight Auger drilling is perfect for those who want to take care of withstanding soil shifting, especially within the boundaries of the land parcel or near adjacent buildings, prevent landslides or protect other buildings, protect against floods.

Advantages of drilling of CFA piles

Resistance

Resistance to crushing, heaving, and lateral loads.

Differing pile depths and diameters

Possible reach of 9 meters and diameter ranging from 300 mm to 600 mm+.

Suits various types of soil

Possible installation in many soil conditions such as sand, peat, gravel, and where ordinary foundation laying methods do not work.

Low noise

Low noise and zero vibration, therefore, the method is perfect in residential areas with weak soils and high amount of groundwater.

Ensuring quality

Ensuring quality as the installing process is carefully controlled.

Economical solution

It is an economical solution for laying foundation.

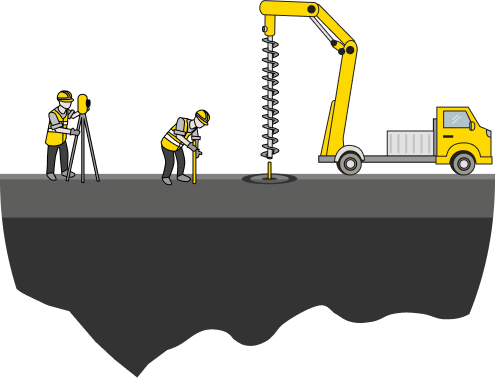

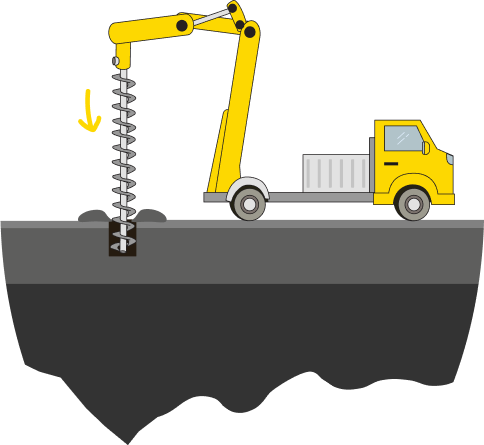

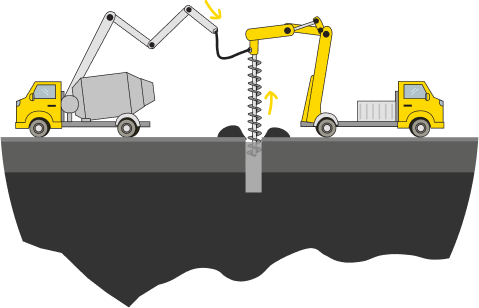

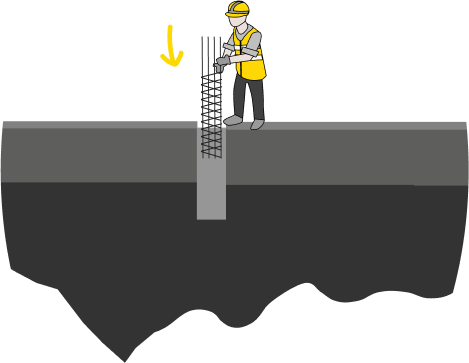

The process of drilling of CFA piles

))

))

))

))

))

))